Clean-up with Gel Permeation Chromatography

Sample clean-up via GPC (gel permeation chromatography) is used for all samples in the analysis of residues and contaminants and is therefore universally applicable.

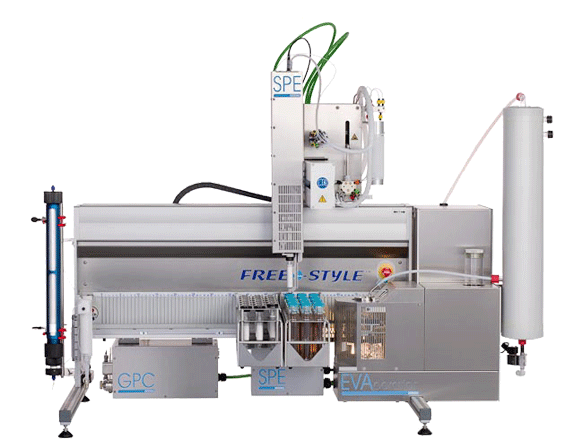

The FREESTYLE GPC is a fully automated chromatographic sample preparation system, that is used for example for clean-up of food, feed and environmental samples. It complies in all areas with the requirements of general methods, e.g. L 00.00-34, EPA 3640A.

Particularly user-friendly is the combination of the FREESTYLE GPC with the EVAporation module. The chosen fraction is collected online in the vacuum chamber and after concentration transferred into one or several vials (e.g. GC vials). The result is a sample, which can be directly introduced into the analyser.

The GPC module consists of a preparative LC-double piston pump with all its advantages e.g. minimising pulsation. With a flow rate of e.g. 5 mL/min, the preparative pump incurs only a small load and the maintenance requirements are thus extremely low. An analytical pump is optionally available

Proven clean-up technology combined with technical finesse

|

|

Trust is good, control is better

When using GPC, significant amounts of solvent occur. In order to protect user and laboratory, the process is controlled at significant points of the system. Parameters can be set individually.

- Under-pressure: normally due to leakages. An instant shut down of the pump prevents the uncontrolled leakage of a large amount of solvents.

- Over-pressure: Might lead to damage of the columns bed material or leakage of the system. With a special low-pressure sensor, the pressure is monitored and on reaching the set value, the system will be shut down. Over-pressure can be caused by clogging of the column.

- Waste sensor: An overfill sensor prevents overflow of the waste container (optional).

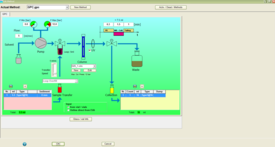

The method set-up for the GPC module is done via a clearly laid out graphic as the basic procedure of sample preparation with GPC is pre-defined: forerun, main run (several fractions possible) and tailings. The user just enters the values and starts the system

Fast Processing of Different Samples

For the automated processing of various samples with different GPC-columns in one sequence LCTech offers an external switching valve (upgrade), which can be simply mounted besides the GPC-pump underneath the FREESTYLE system. Thus the user can select our of up to 4 different GPC-columns per sample in the software. This saves time and work, because a change of columns is not neccessary anymore. However it should be considerd, that all GPC-columns use the same solvent.

For more details please do not hesitate to contact us and write an e-mail to: info@LCTech.de or you can call us: +49 8082 2717-0.